Fixed Competitive Price Cnc Metal Plate Bending Machine - Manual T bending machine WZJ-II T bend tester machine equipment test the coated T bending tester of steel belt 1pc – JINDONGCHENG

Fixed Competitive Price Cnc Metal Plate Bending Machine - Manual T bending machine WZJ-II T bend tester machine equipment test the coated T bending tester of steel belt 1pc – JINDONGCHENG Detail:

Scope of application:

Film flexibility is a measure of paint one of the important indicators of the new varieties of

paint formulations of screening applications have great reference value.

The WZJ-II T-Bending Tester is a new model for testing the flexibility of coatings. It is

suitable for testing the T-Bending Tester of coated steel sheets and strips, as well as

T-Bending Test instrument.

Main Specifications:

One bend angle <45 °

Flatten the body stroke: ≥ 10mm

Test sample plate (steel, aluminum) Thickness: 0.5 ~ 1.0mm

Pressure plate (steel, aluminum) width: ≤ 100mm

Machine weight: 50kg

Dimensions: 300 * 300 * 190mm

Working principle:

Through the rotation of the left handle, the square bending buckle bending pieces parallel to

the shape of <45 ° angle: turn the right handle, driven by the crank lift mechanism so that the

triangle bending fast rise or fall, the specimen clamping or pressure Flat, form a T-bend.

The main structure:

Floor and left and right side panels.

Gear and crank lift mechanism.

Triangle bent Yaping fast.

Square rotation split pieces.

Guard and handle and other components.

Operation steps:

1. Specification: 400 × 100 (mm)

2. Specimens should be placed in a 23 + 2 ° environment for at least 24h before cutting, and

the test should be carried out under the same conditions.

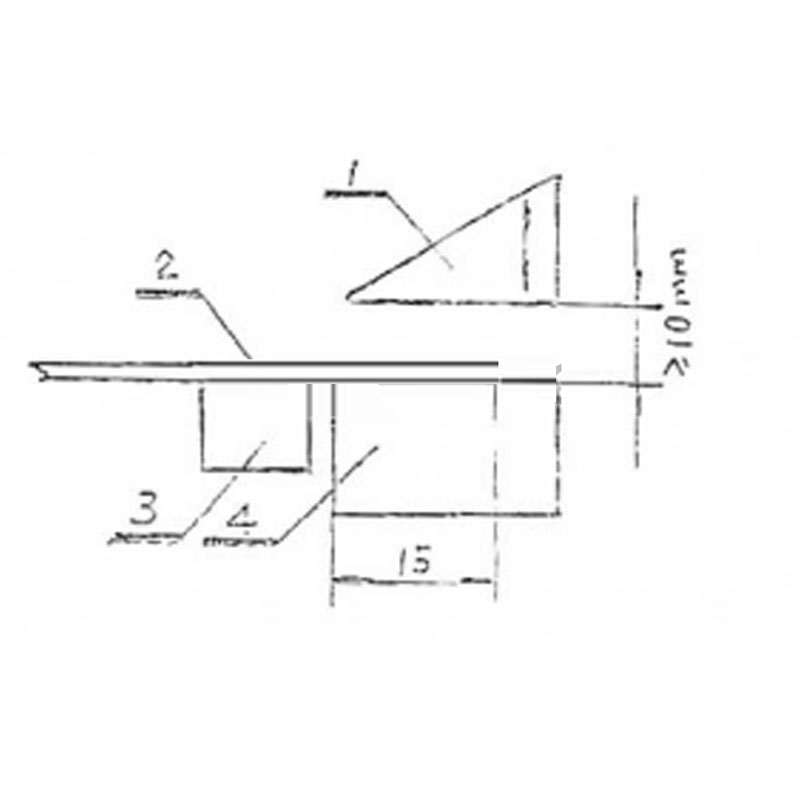

3. Turn the handle on the right side so that the triangular bending crimp block in the middle of

the testing machine picks up (≥10mm): Turn the left handle at the same time, so that the

squareturning split block and the triangular bending flat block become straight with the bottom

surfacestatus. (as the picture shows)

(1) Triangle bending flattened quickly

(2) Sample plate

(3) Square rotation split pieces

(4) The bottom plane

4. The sample plate is side down and into the triangle bending flattened quickly 15mm, turn

the right handle, the triangular bending flattening block down, pressing the sample plate: Turn

the left handle, so that the square rotation split The test board is bent, at which point the test

board forms an angle of <45 °.

5. Turn the handle on the left side, so that the square rotation of the split unit back to its original

position: Turn the right handle, so that the triangle bending flattening block, remove the sample

plate.

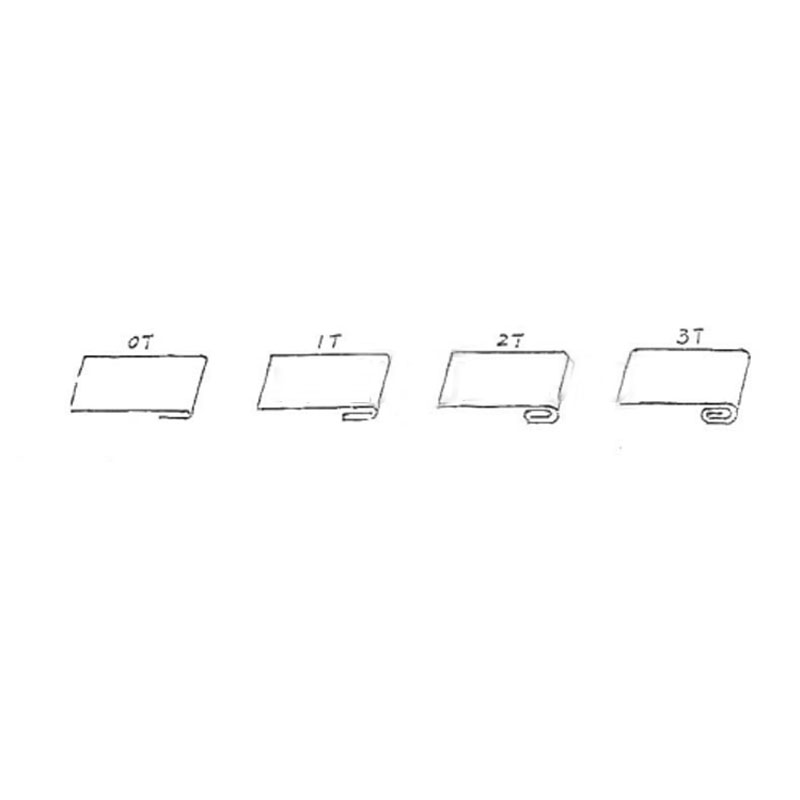

6. Will form a trial class <45 ° angle into the triangular bending flattening block: Turn the right

handle, the triangle bend flattening block down, then the angle of the test plate to be compacted,

the shape of a head is Thickness dimension arc and two parallel faces. That is to complete the

“OT” bend.

7. Repeat the above test procedure to compact the bend of the test plate “OT” and bend and

flatten it so that there is an intermediate layer of test plate thickness at the bend. That completed

the “IT” test.

8. Follow the above steps to repeat the experiment, you can get “2T, 3T” … … Bending (as shown)

Experimental results to determine:

Use Scotch tape (≥0.25N / mm) against the curved surface of the test, flatten the tape with

your fingers, and then peel it off in the direction perpendicular to the coating surface to check if

the coating is peeled off or peeled off Determine the flexibility of the coating.

Caution:

1. When the specimen is bent at IT, there should not be any obvious gap at the bending surface.

2. Coating damage within 10mm from the edge is not taken into account.

3. In order to facilitate the transport, the test machine out of the company, the two handles are

not installed on the host. After the user devanning, with the wrench will be installed on the host

two handles the appropriate position, and be careful to tighten.

Product detail pictures:

Related Product Guide:

Qatar Airways: AI water cart brake failed, hit our plane at Kolkata Airport, says Qatar Airways | India Business News | Portable Siding Brake

Warnings, disposal at issue in lawsuit over fatal steel drum explosion | 48 Box And Pan Brake

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Fixed Competitive Price Cnc Metal Plate Bending Machine - Manual T bending machine WZJ-II T bend tester machine equipment test the coated T bending tester of steel belt 1pc – JINDONGCHENG , The product will supply to all over the world, such as: Chile , Congo , Barcelona , With the development and enlargement of mass clients abroad, now we've set up cooperative relationships with many major brands. We've our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the "quality first, customer first, We are provideing high-quality, low-cost items and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

We have been looking for a professional and responsible supplier, and now we find it.